Aluminum laminate surface

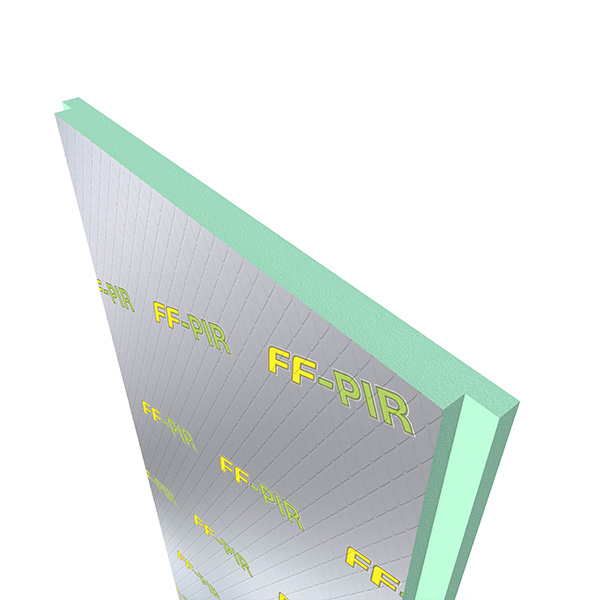

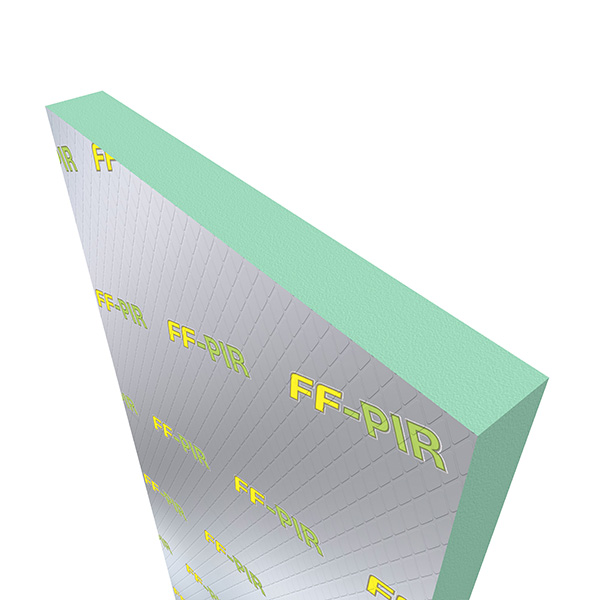

FF-PIR ALK INSULATION PANELS WITH TONGUE AND GROOVE ON ALL SIDES

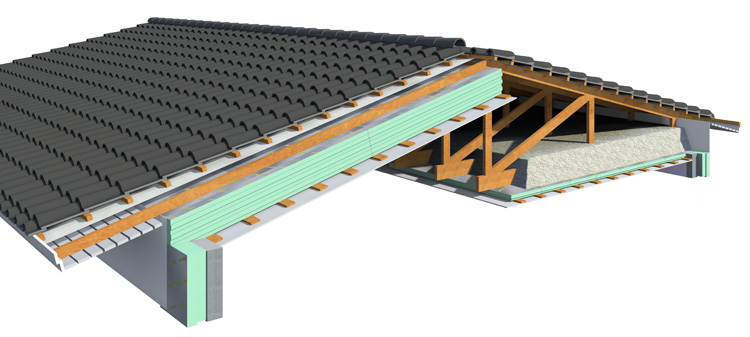

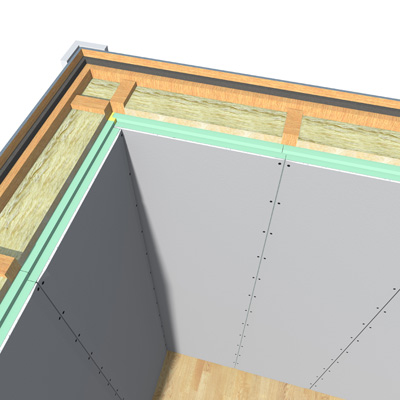

FF-PIR ALK insulation panels can be used for thermal insulation in both repair and new construction. FF-PIR panels can be used as thermal insulation in various roofs and walls as well as saunas. The declared thermal conductivity (λD) of the panels is 0.022 W/mK, which means that the best possible insulation capacity for a structure can be ensured using thinner insulation panels. The panel is covered with a diffusion-proof aluminum laminate surface on both sides. The panels also function as vapor barrier within the structure, which means that the installation of a separate vapor barrier layer is not required. If the entire structure is built using FF-PIR insulation, a separate wind-protective layer on the outside of the structure is also not needed. The fire class of the insulating foam component of FF-PIR insulation is D-s2, d0. FF-PIR insulation panels are produced in widths ranging from 20 to 240 mm at 10 mm intervals, and most thicknesses are readily available as stock products. The panels measure 600 x 2 400 mm, which allows for easy transportation and relocation in narrow spaces. The panels can also be installed horizontally in relation to the frame studs.

Material:

Foam: Polyurethane (polyisocyanurate)

Coating: The insulation of covered on both sides by diffusion-proof aluminum laminate

Color: Foam color mint green

| Product | Size | Units/package | Packages/pallet |

| FF-PIR 30 ALK | 30 x 600 x 2400 mm | 10 | 8 |

| FF-PIR 40 ALK | 40 x 600 x 2400 mm | 10 | 6 |

| FF-PIR 50 ALK | 50 x 600 x 2400 mm | 8 | 6 |

| FF-PIR 70 ALK | 70 x 600 x 2400 mm | 6 | 6 |

| FF-PIR 80 ALK | 80 x 600 x 2400 mm | 5 | 6 |

| FF-PIR 90 ALK | 140 x 600 x 2400 mm | 4 | 6 |

| FF-PIR 100 ALK | 100 x 600 x 2400 mm | 4 | 6 |

| FF-PIR 120 ALK | 120 x 600 x 2400 mm | 3 | 6 |

| FF-PIR 130 ALK | 130 x 600 x 2400 mm | 3 | 6 |

| FF-PIR 140 ALK | 140 x 600 x 2400 mm | 3 | 6 |

| FF-PIR 150 ALK | 150 x 600 x 2400 mm | 2 | 8 |

| FF-PIR 160 ALK | 160 x 600 x 2400 mm | 2 | 8 |

| FF-PIR 200 ALK | 200 x 600 x 2400 mm | 2 | 6 |

| FF-PIR 240 ALK | 240 x 600 x 2400 mm | 2 | 6 |

The minimum order for products with special dimensions or a thickness / method of fitting not listed in the price catalog is 30 m3. All products are available with a flat edge, rabbet or tongue and groove. The delivery amount for any FF-PIR special product may vary by +0–30 m2 in relation to the ordered amount.

Thermal conductivity: λ declared 0.022 W/mK

Method of fitting: Tongue and groove on all sides

Coating: Diffusion-proof aluminum laminate

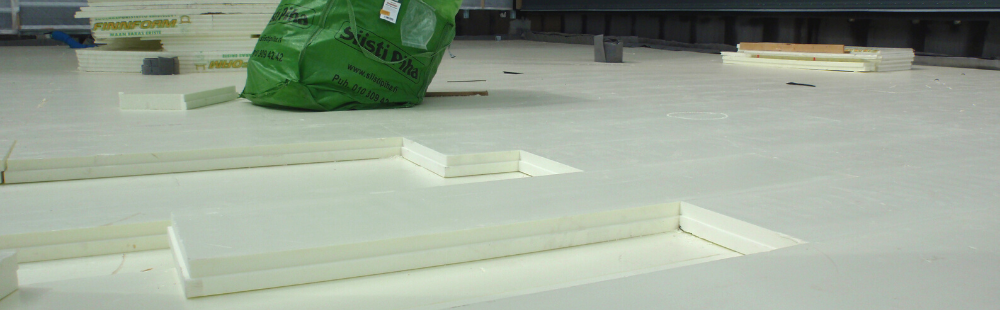

FF-PIR ALI INSULATION PANELS WITH FLAT EDGE ON ALL SIDES

FF-PIR ALI insulation panels can be used for thermal insulation in both repair and new construction. FF-PIR panels can be used as thermal insulation in various roofs, walls, and saunas. In addition, the panels can also be used as thermal insulation panels for windows, doors, and ventilators. The declared thermal conductivity (λD) of the panels is 0.022 W/mK, which means that the best possible insulation capacity for a structure can be provided using thin insulation panels. The panel is covered with a diffusion-proof aluminum laminate surface on both sides. The fire class of the insulating foam component of FF-PIR insulation is D-s2, d0.

| Product | Size | Units/package | Packages/pallet |

| FF-PIR 20 ALI | 20 x 600 x 2400 mm | 20 | 6 |

| FF-PIR 50 ALI | 50 x 600 x 2400 mm | 8 | 6 |

| FF-PIR 100 ALI | 100 x 600 x 2400 mm | 4 | 6 |

| FF-PIR 150 ALI | 150 x 600 x 2400 mm | 2 | 8 |

Thermal conductivity: λ declared 0.022 W/mK

Method of fitting: Flat edge

Coating: Diffusion-proof aluminum laminate

FF-PIR 40 ALS RENOVATION PANEL

FF-PIR 40 ALS is a renovation board with joints on the longer edges into which a 20 x 100 mm board or plywood strip is installed, to which new interior cladding can be easily fixed. Panel size on 40 x 600 x 2600 mm. The panel has a diffusion-proof aluminum laminate surface on both sides. The FF-PIR 40 ALS renovation panel was designed for supplementary thermal insulation in interior walls and roofs. The FF-PIR 40 ALS renovation panel functions as thermal insulation and vapor barrier within the structure. The declared thermal conductivity of FF-PIR insulation products is 0.022 w/mk. Particularly in renovation projects, this allows for maximal utilization of living space without thick insulation. FF-PIR insulation products can be used to easily create leak-proof structures, which is very important from the perspective of energy efficiency.

| Product | Size | Units/package | Packages/pallet |

| FF-PIR 40 ALS | 40 x 600 x 2600 mm | 10 | 6 |

Thermal conductivity: λ declared 0.022 W/mK

Method of fitting: Edges of the panel feature grooves for 20 ×100 mm wood strips

Coating: Diffusion-proof aluminum laminate

FF-PIR 100 AND 150 K600 PANELS FOR USE BETWEEN STUDS

The FF-PIR 100 and 150 k600 insulation panels were designed to be installed in between studs. The panel size is 100/150 x 520 x 2 600 mm. The panels are designed for 600 mm stud spacing (k600). The panels are suitable for use in both the ceiling and walls. Both sides of the panel are covered with a diffusion-proof aluminum laminate. The panels have a flat edge on the longer sides with a tongue and groove at the ends. The k600 panel facilitates installation and minimizes waste when installed between studs. The declared thermal conductivity of FF-PIR insulation products is 0.022 w/mk.

| Product | Size | Units/package | Packages/pallet |

| FF-PIR 100 K600 | 100 x 520 x 2600 mm | 4 | 6 |

| FF-PIR 150 K600 | 150 x 520 x 2600 mm | 2 | 8 |

Thermal conductivity: λ declared 0.022 W/mK

Method of fitting: Flat edge on the long sides, shorter sides with tongue and groove

Coating: Diffusion-proof aluminum laminate

FF-PIR 100 AND 150 K900 PANELS FOR USE BETWEEN STUDS

The FF-PIR 100 and 150 k900 insulation panels were designed to be installed in between roof trusses. The panel size is 100/150 x 600 x 820 mm. The panels are designed for 900 mm spacing (k900). The panels are suitable for use in both the roof and walls. The panel has a diffusion-proof aluminum laminate surface on both sides. The panels have a tongue and groove on the longer sides with a flat edge at the ends. The panel facilitates installation and minimizes waste when installed between studs. The declared thermal conductivity of FF-PIR insulation products is 0.022 w/mk.

| Product | Size | Units/package | Packages/pallet |

| FF-PIR 100 K900 | 100 x 600 x 820 mm | 8 | 6 |

| FF-PIR 150 K900 | 150 x 600 x 820 mm | 4 | 8 |

Thermal conductivity: λ declared 0.022 W/mK

Method of fitting: Flat edge on the short sides, long sides with tongue and groove

Coating: Diffusion-proof aluminum laminate

FF-PIR ALK, Aluminum laminate surface

- Dimensions

- Technical details

| Value | Unit | According to EN 13165 | Standard | |

|---|---|---|---|---|

| Length | 2400 | mm | ||

| Width | 600 | mm | ||

| Thickness | 30 - 240 | mm |

| Value | Unit | According to EN 13165 | Standard | |

|---|---|---|---|---|

| Thermal conductivity | EN 13165 | |||

| λ Declared | 0,022 | W/(m K) | EN 12667, EN 12939 | |

| Thermal resistance, Rᴅ | 1,35 - 10,90 | m²K/W | EN 12667, EN 12939 | |

| Compressive strength, short-term 45 days, ≥ 30mm | > 100 | kPa | CS(10/Y)100 | EN 826 |

| Design stability | DS (70,90)4 | EN 1604 | ||

| Proportional change in width | ≤ 1 | % | ||

| Proportional change in length | ≤ 1 | % | ||

| Proportional change in thickness | ≤ 4 | % | ||

| Design stability | DS (-20,-)2 | EN 1604 | ||

| Proportional change in width | ≤ 0,5 | % | ||

| Proportional change in length | ≤ 2 | % | ||

| Proportional change in thickness | ≤ 2 | % | ||

| Water absorption when fully immersed in the long-term | < 2 | til.-% | WL(T)2 | EN 12087 |

| Fire class | E | Euroluokka | EN 13501-1 | |

| Fire class of the foam | D-s2, d0 | |||

| Service temperature | -50 ...+100, lyhytaik. +200 | C° | ||

| Indoor air emission class | M1 |

FF-PIR ALI, Aluminum laminate surface

- Dimensions

- Technical details

| Value | Unit | According to EN 13165 | Standard | |

|---|---|---|---|---|

| Length | 2400 | mm | ||

| Width | 600 | mm | ||

| Thickness | 20 - 240 | mm |

| Value | Unit | According to EN 13165 | Standard | |

|---|---|---|---|---|

| Thermal conductivity | EN 13165 | |||

| λ Declared | 0,022 | W/(m K) | EN 12667, EN 12939 | |

| Thermal resistance, Rᴅ | 0,90 - 10,90 | m²K/W | EN 12667, EN 12939 | |

| Compressive strength, short-term 45 days, ≥ 30mm | > 100 | kPa | CS(10/Y)100 | EN 826 |

| Design stability | DS (70,90)4 | EN 1604 | ||

| Proportional change in width | ≤ 1 | % | ||

| Proportional change in length | ≤ 1 | % | ||

| Proportional change in thickness | ≤ 4 | % | ||

| Design stability | DS (-20,-)2 | EN 1604 | ||

| Proportional change in width | ≤ 0,5 | % | ||

| Proportional change in length | ≤ 0,5 | % | ||

| Proportional change in thickness | ≤ 2 | % | ||

| Water absorption when fully immersed in the long-term | < 2 | til.-% | WL(T)2 | EN 12087 |

| Fire class | E | Euroluokka | EN 13501-1 | |

| Fire class of the foam | D-s2, d0 | |||

| Service temperature | -50 ...+100, lyhytaik. +200 | C° | ||

| Indoor air emission class | M1 |

FF-PIR 40 ALS, Aluminum laminate surface

- Dimensions

- Technical details

| Value | Unit | According to EN 13165 | Standard | |

|---|---|---|---|---|

| Length | 2600 | mm | ||

| Width | 600 | mm | ||

| Thickness | 40 | mm |

| Value | Unit | According to EN 13165 | Standard | |

|---|---|---|---|---|

| Thermal conductivity | ||||

| λ Declared | 0,022 | W/(m K) | EN 12667, EN 12939 | |

| Thermal resistance, Rᴅ | 1,80 | m²K/W | EN 12667, EN 12939 | |

| Compressive strength, short-term 45 days, ≥ 30mm | > 100 | kPa | CS(10/Y)100 | EN 826 |

| Design stability | DS (70,90)4 | EN 1604 | ||

| Proportional change in width | ≤ 1 | % | ||

| Proportional change in length | ≤ 1 | % | ||

| Proportional change in thickness | ≤ 4 | % | ||

| Design stability | DS (-20,-)2 | EN 1604 | ||

| Proportional change in width | ≤ 0,5 | % | ||

| Proportional change in length | ≤ 2 | % | ||

| Proportional change in thickness | ≤ 2 | % | ||

| Water absorption when fully immersed in the long-term | < 2 | til.-% | WL(T)2 | EN 12087 |

| Fire class | E | Euroluokka | EN 13501-1 | |

| Fire class of the foam | D-s2, d0 | |||

| Service temperature | -50 ...+100, lyhytaik. +200 | C° | ||

| Indoor air emission class | M1 |

FF-PIR K600, Aluminum laminate surface

- Dimensions

- Technical details

| Value | Unit | According to EN 13165 | Standard | |

|---|---|---|---|---|

| Length | 2600 | mm | ||

| Width | 520 | mm | ||

| Thickness | 100, 150 | mm |

| Value | Unit | According to EN 13165 | Standard | |

|---|---|---|---|---|

| Thermal conductivity | ||||

| λ Declared | 0,022 | W/(m K) | EN 12667, EN 12939 | |

| Thermal resistance, Rᴅ | 4,55 - 6,80 | m²K/W | EN 12667, EN 12939 | |

| Compressive strength, short-term 45 days, ≥ 30mm | > 100 | kPa | CS(10/Y)100 | EN 826 |

| Design stability | DS (70,90)4 | EN 1604 | ||

| Proportional change in width | ≤ 1 | % | ||

| Proportional change in length | ≤ 1 | % | ||

| Proportional change in thickness | ≤ 4 | % | ||

| Design stability | DS (-20,-)2 | EN 1604 | ||

| Proportional change in width | ≤ 0,5 | % | ||

| Proportional change in length | ≤ 2 | % | ||

| Proportional change in thickness | ≤ 2 | % | ||

| Water absorption when fully immersed in the long-term | < 2 | til.-% | WL(T)2 | EN 12087 |

| Fire class | E | Euroluokka | EN 13501-1 | |

| Fire class of the foam | D-s2, d0 | |||

| Service temperature | -50 ...+100, lyhytaik. +200 | C° | ||

| Indoor air emission class | M1 |

FF-PIR K900, Aluminum laminate surface

- Dimensions

- Technical details

| Value | Unit | According to EN 13165 | Standard | |

|---|---|---|---|---|

| Length | 820 | mm | ||

| Width | 600 | mm | ||

| Thickness | 100, 150 | mm |

| Value | Unit | According to EN 13165 | Standard | |

|---|---|---|---|---|

| Thermal conductivity | EN 13165 | |||

| λ Declared | 0,022 | W/(m K) | EN 12667, EN 12939 | |

| Thermal resistance, Rᴅ | 4,55 - 6,80 | m²K/W | EN 12667, EN 12939 | |

| Compressive strength, short-term 45 days, ≥ 30mm | > 100 | kPa | CS(10/Y)100 | EN 826 |

| Design stability | DS (70,90)4 | EN 1604 | ||

| Proportional change in width | ≤ 1 | % | ||

| Proportional change in length | ≤ 1 | % | ||

| Proportional change in thickness | ≤ 4 | % | ||

| Design stability | DS (-20,-)2 | EN 1604 | ||

| Proportional change in width | ≤ 0,5 | % | ||

| Proportional change in length | ≤ 2 | % | ||

| Proportional change in thickness | ≤ 2 | % | ||

| Water absorption when fully immersed in the long-term | < 2 | til.-% | WL(T)2 | EN 12087 |

| Fire class | E | Euroluokka | EN 13501-1 | |

| Fire class of the foam | D-s2, d0 | |||

| Service temperature | -50 ...+100, lyhytaik. +200 | C° | ||

| Indoor air emission class | M1 |